Temperature monitoring using FBG

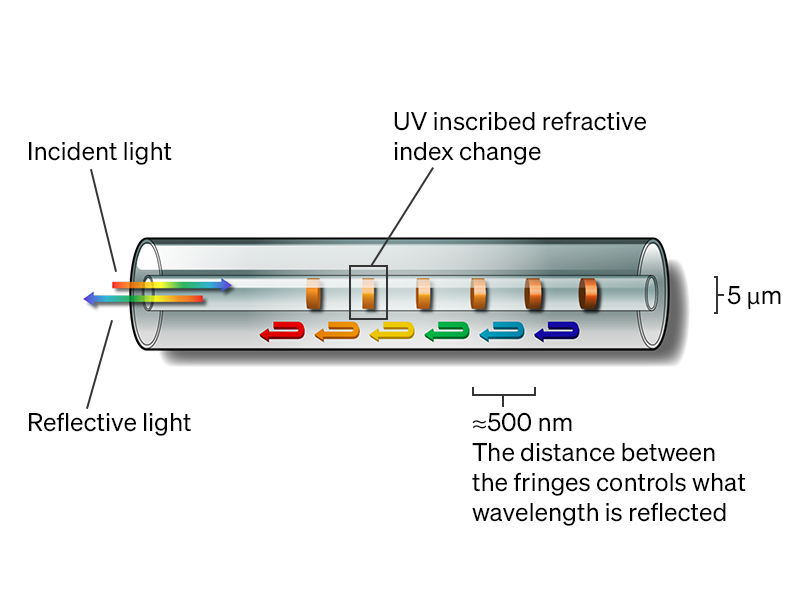

The basic principle of measuring temperature with FBGs is that the reflected wavelength depends on the grating characteristics (period, modulation) and is influenced by the ambient conditions such as strain and temperature. This allows the utilisations of FBGs as sensor for strain and temperature.

In the case of temperature monitoring, the Bragg wavelength is a function of the temperature. This temperature dependence results from changes of the refractive index of the fiber as well as from thermal expansion of the glass material.

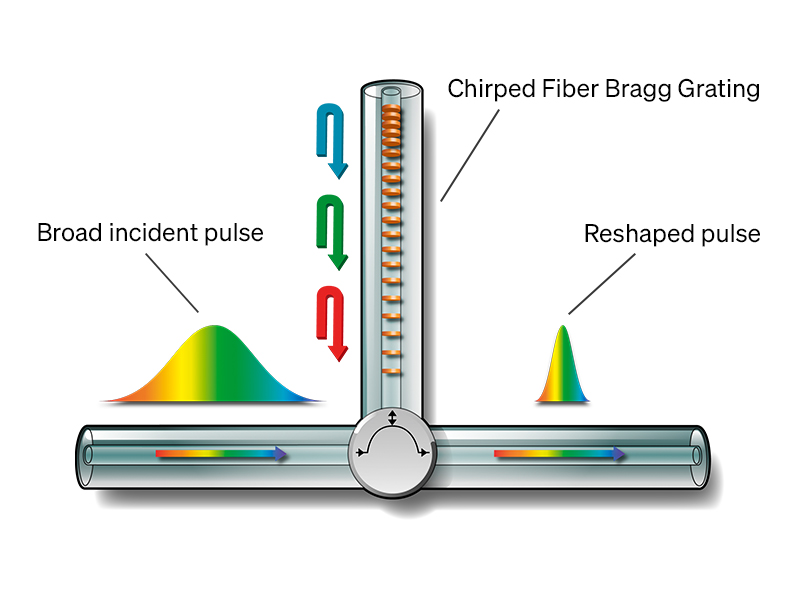

Proximion's DCM principle

Dispersion (pulse broadening) is compensated for by precisely chirped FBGs allowing faster wavelengths to travel longer distances than slower, thereby reshaping the pulse. Without FBGs the pulses will eventually start to overlap and bit errors will occur.

Proximion is the only company that offers continuous FBGs, hence providing future proof solutions that are independent of channel plan and modulation format.